The calibration of process pressure instruments is critical for maintaining accuracy which, in turn, is necessary for the successful execution of processes. Spanning across all industries whether Aeospace, Petrochemical, Defence, Oil & Gas, Research & Development Laboratories, Metrology, Automotive, Manufacturing, etc. the calibration and periodic re-calibration of pressure instruments is an extremely important activity, which needs to be conducted at regular intervals

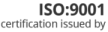

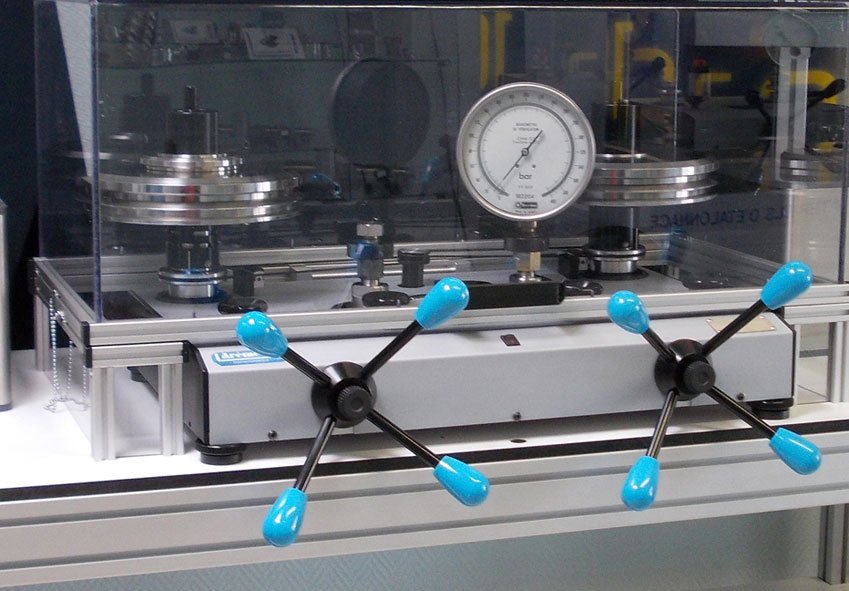

Pneumatics differential dead weight Tester

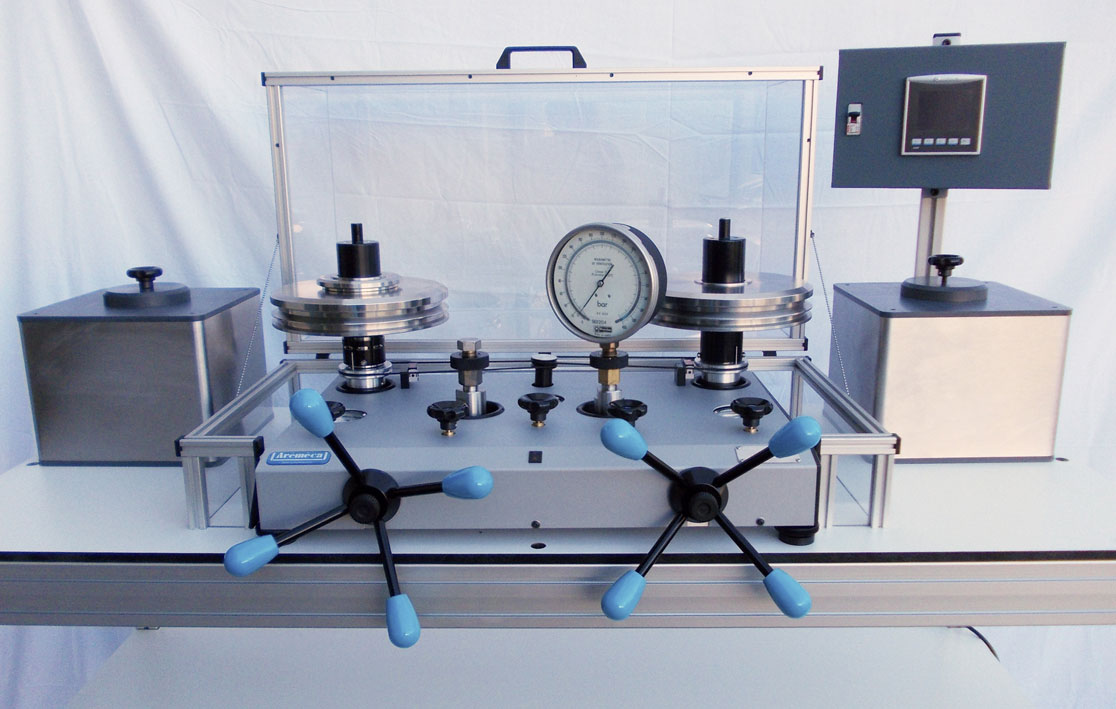

SBE offer both primary pressure standards (ie. Deadweight Pressure Testers, also known as DWT and typically installed at Metrological Laboratories) as well as Pressure Comparator type instruments (which rely on reference or Master Pressure Gauges/Instruments and are the most popular type of instruments being utilized in general industry). SBE work in close co-operation with M/S AREMECA (France), specialist manufacturers of high precision pressure calibration instruments for pressures as high as 10,000 Bar/145,000 PSI. A complete range of pneumatic as well as hydraulic pressure calibration equipment is offered. Customized calibration solutions, involving single or multiple stations, combinations of Comparator and Primary Standard calibration devices, ranging from very low pressures to extremely high pressures, are offered.

Applications in high pressure calibration of process instruments exist in LDPE Petrochemical Plants, Space Research, Deepsea Ocean Research, Offshore Oil & Gas and Geophysical Research Laboratories, Diamond Anvil Cell Installations, Nuclear Power, Atomic Research, etc. Pressure Comparator pumps are often used to re-calibrate instruments at pressures of 30,000 PSI / 2,000 BAR, 60,000 PSI / 4,000 BAR and 100,000 PSI / 7,000 BAR and even as high as 145,000 PSI / 10,000 BAR. For Pressure Comparator type devices, the pressure generating instruments – such as hand-spindle pumps or electric motor driven spindle pumps - need to be high precision instruments possessing minimum hysteresis and a high degree of repeatability. These pressure generators are as important for the calibration as the actual master reference pressure instrument, as the two work in tandem to generate & control the precise reference pressures required to successfully calibrate pressure gauges or pressure transmitters.

Precision pressure generators are also used for generation of precise forces, for force calibration studies and re-calibration of force instruments. Eminent R&D institutes such as the National Physical Laboratory in New Delhi, have been using the robust, highly reliable precision high pressure hand spindle pumps manufactured by NOVA SWISS since over 30 years. Since the year 2000, SBE have been supporting NOVA SWISS customers with spare parts and repair services, as well as upgrade to new NOVA SWISS pumps and also complete systems including pressure gauges/pressure transmitters, valves, fittings, etc. to enable pressure generation and control.

Hydraulic dead weight Tester

SBE also offer the complete range of Haskel air-driven high pressure gas boosters for use as reference pressure sources for precision electronic pneumatic pressure calibrators such as from ARMANO (Germany), WIKA (Germany), FLUKE (USA), MENSOR (USA), Druck, Des Granges & Huot, etc. Our specialist team is well experienced in designing and manufacturing compact gas booster systems, fitted with high quality, high precision gas pressure control regulators and other high quality controls to enable precise control of gas pressures to 2,100 Bar/30,000 PSI. Should the need arise for even higher gas pressures, SBE offer electric motor driven diaphragm type NOVA SWISS gas compressors for pressures to 3,000 Bar / 45,000 PSI and NOVA SWISS gas pressure intensifiers capable of boosting pressures to 10,000 Bar / 145,000 PSI.

High Performance Dead Weight Tester

The same precision hand spindle pumps from NOVA SWISS may also be utilized for conducting catalyst injection studies in laboratories and pilot plants, while electric motor driven Peroxide injection pumps find application in LDPE production processes. Phase flow pressurization is accomplished in an easy, repeatable manner with high precision control, using these multi-turn high pressure injection pumps. Combination units with “coarse control” pumps along with spindle pumps, enable quicker pressurization of process reactor vessels. Standard pumping systems are available for pressures of 2,000 Bar, 4000 Bar and 7,000 Bar and special order systems are available for pressures to 10,000 Bar.

Whether for Pressure Calibration or Force Generation for Force Calibration, SBE are able to offer solutions with internationally reputed equipment sourced from the world’s leading manufacturers